|

|

3D Printer Enclosure

| Temperature Controlled 3D Printer Enclosure 2.1 (2020-02-25) • 11MB |

|

|

3D Printer STL files for temperature controlled 3D printer enclosure with motion sensor controlled LED lights. JocysCom-Enclosure.zip file size ~11MB.

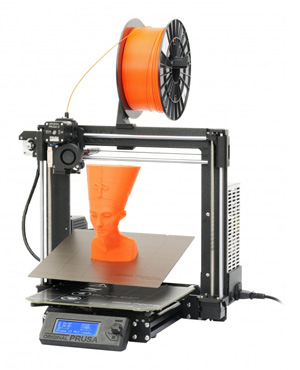

Below you will find parts and tools, which will help you to assemble enclosure. Enclosure fits Prusa3D i3 MK3 printer. If you noticed mistakes, have questions or suggestions, please write to info@jocys.com • Project on Thingiverse.com or Printables.com

Maximum temperature inside enclosure depends on temperature of the room and heated 3D printer bed. Stable higher temperature inside enclosure reduces warping and detaching of bigger parts from the plate. Control precision is 1°C. HOW IT WORKS: If temperature rises +1°C above set limit (for example, set limit is +40°C and temperature rises to +41°C), two “MH1210A” controllers start fans (ventilation) and drop temperature to +40°C. Tested temperature limit inside enclosure +46°C (room +28°C, heated bed +85°C, extruder +240°C). In order to achieve even higher temperatures inside enclosure, insulation must be added to windows and door. All enclosure parts (cut perspex sheets, ~2kg PETG filament (20% infill), bottle of Windex, smoke alarm, cables, controllers, etc.) cost me about €260 (tools are not included).

E3D V6 HotEnd is rated to 40°C ambient operating temperature. As you approach that temperature, cooling efficiency is reduced, allowing more heat up past the heatbreak. This can cause low temperature filament to soften in the mechanism to cause feed problems. Therefore, for PETG filament, I set both enclosure fans to keep 35°C inside enclosure.

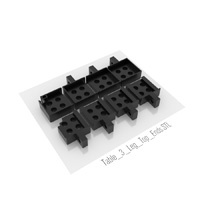

Parts were printed from PETG with Prusa3D i3 MK3 Printer. If your printer is not precise enough, printed parts may not fit into each other. To test, if your printer is precise enough, you can print and try to fit into each other these two parts from “Table_3_Leg_Top_Ends.STL” file. Spaces between some parts are 0.1mm only.

1mm spaces between perspex sheets and table are for even ventilation.

2 temperature controller-fan sets are for safety, in case one set malfunctions.

If you made your own updates or changes, related to this project, please send me a link. I will add this link to your work on this page.

|

|

The owner of this website is a participant in the Amazon EU Associates and Amazon Services LLC Associates Program...

The owner of this website is a participant in the Amazon EU Associates and Amazon Services LLC Associates Program, an affiliate advertising program designed to provide a means for sites to earn advertising fees by advertising and linking to Amazon.com / Amazon.co.uk / Amazon.ca / Amazon.de / Amazon.it / Amazon.fr / Amazon.es

|

|

Creative Commons License

BY • Attribution - Credit must be given to the creator

SA • ShareAlike - Adaptations must be shared under the same terms |

| This license allows reusers to distribute, remix, adapt, and build upon the material in any medium or format, so long as attribution is given to the creator. The license allows for commercial use. If you remix, adapt, or build upon the material, you must license the modified material under identical terms. |

Jocys.com

Comments • 0

|

|

|

Updates

Updates

2.1 (2020-02-25) • Filament Guide for Filament Holder Connector added and for Prusa3D Filament Holder updated.

2.0 (2019-03-12) • Internal cable connection boxes removed. Motion sensor moved from tabletop bottom to front.

1.9 (2019-02-19) • Controller slots, front panels and stoppers changed - easier to insert controllers.

0.1 (2018-07-04) • ...

Jocys.com

|

|

|

Parts

Parts

|

2018-12Ikea • LACK Table 55x55cm€6

3 x Ikea LACK table.

Article no: 200.114.08

Length: 75 cm

Width: 55 cm

Height: 5 cm

Weight: 3.80 kg

|

|

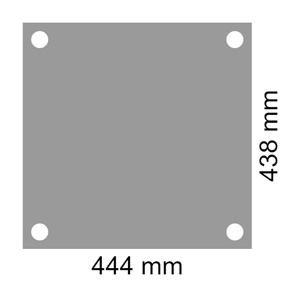

2018-12Perspex • Clear Perspex 000 3x444x438mm€12

PerspexSheet.uk cutting done for my order was not very precise (±1mm). You may try other company with more precise equipment for cutting and drilling plastic.

4 x Perspex sheet with 4 corner holes (3 windows and 1 door).

Hole Size: 8mm

Hole (edge) Distance (from sheet edge): 5mm

Clear Perspex 000

Shape: Rectangle

Thickness: 3 mm

Length: 444 mm

Width: 438 mm

Finish: Polished & Buffed

|

|

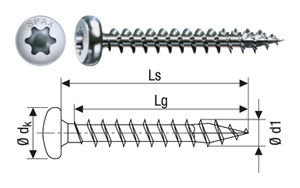

2018-12SPaX • Screws 5x25 0201010500253€10

1 x Box with 200 screws.

EAN: 4003530166303

SPAX-No.: 0201010500253

Thread diameter d1: 5 mm

Length total Ls: 25 mm

Head diameter dk: 9,9 mm

Partial thread length LgT: 22 mm

BIT size T: 20

|

|

2018-12Noctua • NF R8 redux-1800 3-pin€11

2 x Noctua NF-R8 redux-1800 fan.

This fan has 3-pin connector. "PWM" fan models have 4-pin connectors.

Size: 80x80x25 mm

Mounting hole spacing: 71,5x71,5 mm

Connector: 3-pin

Bearing: SSO-Bearing

Rotational Speed: (+/- 10%) 1800 RPM

Airflow: 53,3 m³/h

Acoustical Noise: 17,1 dB(A)

Max. Input Power: 1,32 W

Max. Input Current: 0,11 A

Voltage: 12 V

|

|

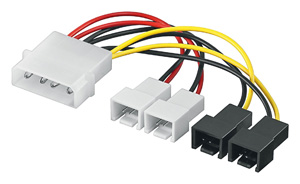

2018-12Amazon • Molex 4-pin to 3-pin Fan Power Adapter Converter Cable€3

1 x Molex cable to cut and connect fans to MH1210A temperature controllers.

4-pin LP4 to 3-pin TX3 Fan Power Adapter Converter Cable.

Simultaneous connection of 4 fans with 3-pin connector (CPU fan, case fan etc.) direct to the power supply.

|

|

2018-12MeiHang • MH1210A 12V Temperature Controller€10

I bought and used "KKmoon version" from Amazon.co.uk

2 x MH1210A 12V temperature controller.

Model: MH1210A

1 x Temperature Controller

1 x Temperature Sensor

1 x Instruction Manual

Working voltage: 12V ±10%

Rated current: 10A

Power consumption: ≤3W

Measurement range: -40~120 °C

Measurement precision: 0.1 °C

Measurement error: ±0.5 °C

Control range: -40~120 °C

Control precision: 1 °C

Working temperature: -20~70 °C

Temperature sensor: NTC 25 °C=10K B3435

Item size: 8.5x7.5x3.5cm

|

|

2018-12Ustellar • 3m LED Strip Lights 1500lm 12V 3000K Warm White€19

1 x Ustellar LED light set - 8mm width.

This LED stripe can be cut into 40cm pieces for 3D printed LED stripe holder.

1 x LED power adapter connected to... temperature controller, fan, motion sensor, LED stripe.

Model: UT666006-WW-UK

1 x LED Light Strip

1 x Power Adapter

1 x Hand Wave Switch

3 x L-shape Connector

2 x 0.5m Cable Connector

6 x Screw Clip (for strip light)

6 x Cable Clip (for black cable)

Wattage: 12W

Output Voltage: 12V DC

Input Voltage: 100-240V AC

Luminous Flux: 1500lm

Lifespan: 50,000 hours

Colour Temperature: 3000K (Warm White)

Switch Type: Hand Wave Activated Control

|

|

2018-12CPC Farnell • Pro Elec 12V, 3A AC/DC Power Supply Adapter PEL00852€9

1 x Power adapter connected to... temperature controller, fan.

Fixed UK plug

Conforms to: UL CE ErP VI

Built-in over-Voltage, over-current and short circuit protection

Level VI efficiency regulations compliant

Universal input: 90~264V AC, 47~63Hz

Straight DC connector model: PEL00582

Right-angled DC connector model: PEL00853

|

|

2018-12Tuodi • TDL-2024 5V-24V Motion Sensor Switch€7

1 x TDL-2024 motion sensor switch.

I didn't want to turn on-off lights manually, so I used motions sensor.

Model: TDL-2024

Operating voltage: 5V-24V DC

Operating temperature: -20 °C ~ +50 °C

Wiring: Male and female pin (input / output)

Output mode: Sensor Output

Delay Range: The factory setting 15 seconds

Induction way: Passive

Induction angle: 120-degree cone angle

Detecting distance: >3M

Dimension: 63x19.5x18.5mm

|

|

2018-12Magnet Expert • 6x2mm 0.73kg Pull N42 Neodymium Magnet€6

8 x Neodymium magnet for enclosure door.

Glass holders can be modified and replaced in the future by adding stronger magnets at their ends, so acoustic panels could be easily attached or detached to enclosure, when necessary, to reduce printing noise. Magnets, holding acoustic panels in place, would not be necessary with glass holders having |V| shape.

Model: F362-25

• 6mm diameter x 2mm thick.

• +/-0.1mm tolerance.

• Each magnet's north and south pole are on opposite 6mm diameter faces.

• Coated with three layers of nickel, copper and nickel to reduce corrosion and provide a smooth finish.

|

|

2018-12N/A • 5.5mm x 2.1mm 12V DC Power Connectors€0.60

4 x 12V DC female power connector.

3 x Male connectors

Model: QAA-90105

Internal diameter of the plug: 2.1mm

External diameter of the plug: 5.5mm

Pair (Male connector and Female connector)

|

|

2018-12Welleen • WA-0093 Adapter€6

1 x 90 degree adapter for PSU.

Model: WA-0093

IEC 320 C14 Male to IEC 320 C13 female.

The adapter is right angled, and Down angled forward.

|

|

2018-12FireAngel • ST-750 Smoke Alarm€14

1 x Smoke alarm.

If smoke alarm is mounted inside enclosure, keep in mind alarm's recommended operating temperature 4-38°C.

Supply voltage: 3V DC

Battery: 10 year sealed for life Panasonic battery

Technology: Thermoptek

Alarm sound level: 85dB(A) at 3m (minimum)

Installation positions: Ceiling / Wall

Operating temperature: +4°C to+38°C

Storage temperature: -20°C to+60°C

Plastic material: ABS, UL94 VO fire retardant

Warranty: 10 years

Certified to: BS EN 14604: 2005+AC:2008

Barcode: 0816317004064

|

Duplicate Silicone • Optional

Jocys.com

Comments • 0

|

|

|

Tools

Tools

3D Printer

|

2018-05Prusa • i3 MK3€750

• Print technology: Fused Filament Fabrication (FFF) / Fused Deposition Modeling (FDM).

• 0.4mm nozzle (easy changeable) for 1.75 mm filament.

• Build volume 11,025 cm3 (25 x 21 x 21 cm).

• Layer height (layer resolution) from 0.05 mm (50 microns).

• Accuracy: 0.01 x 0.01 x 0.005 mm (10 x 10 x 5 microns).

• Max extruder temperature: 280 °C.

• Max heated bed temperature: 120 °C.

• Supported materials: PLA, ABS, PET, HIPS, Flex PP, Ninjaflex, Laywood, Laybrick, Nylon, Bamboofill, Bronzefill, ASA, T-Glase, Carbon-fibers enhanced filaments, Polycarbonates...

• Integrated LCD and SD card controller (8GB included).

• Automatic mesh bed levelling.

• Heatbed with cold corners compensation (warpless 3D printing from any material).

• Automatic skew axes compensation.

• Hassle free PEI print surface (no glass, no glue, no ABS juice).

• Easy multicolor printing based on layer height.

• 1 kg silver PLA filament included.

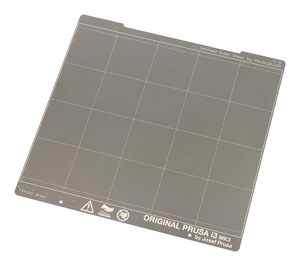

• Removable magnetic spring steel sheet with PEI surface.

• EINSY RAMBo motherboard.

• Silent Trinamic drivers with 256 microstepping.

• Faster printing: 200+ mm/s.

• Sensorless homing for X and Y axes.

• Detection and recovery of shifted layers.

• Improved frame rigidity with aluminium extrusions.

• Power loss detection and recovery.

• Better cooling from both sides of the object.

• Optional WIFI with Octoprint interface included.

• Bondtech extruder drive - filament is driven from both sides.

• Optical filament flow sensor with filament presence and movement detection.

• Automatic loading of filament when filament is inserted.

• Detection of jammed extruder with pause print.

• Both extruder cooling fan and print cooling fan detect RPM. When extruder fan is blocked, the printer will stop to prevent damage of extruder. Same applies for the print cooling fan.

• Extra silent Noctua fan.

• New P.I.N.D.A. 2 probe with included thermistor - faster temperature calibration.

• Room ambient temperature sensor.

|

Uninterruptible Power Supply (UPS) (Optional)

|

2015-10APC • Back-UPS Pro€120-300

You need to disconnect "PSU Power Panic" (black and white twisted) cable from Prusa3D i3 MK3 board. Otherwise, Prusa printer will restart after each power failure.

The Back-UPS Pro family offers guaranteed power protection for high performance computer systems, routers/modems, external storage devices, game consoles and other electronics in your home or business. These UPSs supply electronics with abundant battery backup during outages and stabilize unsafe voltage levels. They also provide power protection from damaging surges and spikes, and allow the use of management software so you get the most out of your UPS. Premium features of this family may include Automatic Voltage Regulation (AVR), an LCD display, Smart Outlets, energy saving functions that reduce electricity use, network manageability, Watchdog, or configurable outlets. Together with the rest of the Back-UPS Pro's standard features, they are the perfect choice to protect your data and keep your system available.

|

Accessory Set

|

2015-01Bosch • X103Ti€50

Click on image to zoom.

18 HSS-TiN metal drill bits, diameter 1-10 mm

7 TC masonry drill bits, diameter 3-8 mm

7 wood drill bits, diameter 3-10 mm • 3mm bit for SPaX screw predrills

3 spade bits, Titanium, diameter 16/22/32 mm • 22mm and 32mm bits for tabletop holes

4 depth stops, diameter 3/5/8/10 mm

40 screwdriver bits:

L = 25 mm

PH 0/0/1/1/2/2/2/3/3/3

PZ 0/0/1/1/2/2/2/3/3/3

S 4/4/6/6/7/7 • S4 bit for 5.5mm x 2.1mm connectors

HEX 3/4/5/6

T 10/10/15/15/20/20/25/25/30/40 • T20 bit for SPaX screws

8 nutsetters, diameter 5/6/7/8/9/10/11/13 mm

4 HCS holesaws, diameter 32/38/45/54 mm • 54mm holesaw for 2 tabletop fan holes

1 diameter gauge

1 countersink

1 tape measure • for finding tabletop center (275mm)

1 spirit level

1 Allen key

1 universal holder, magnetic • for pushing out small parts from their holes if needed

1 adapter for nutsetters

1 adapter for holesaws

1 hammer • for pushing some parts into each other if needed

1 adjustable spanner

1 pair of long nose pliers • for motion sensor insertion

1 pair of combination pliers

|

Screwdriver

|

2020-01Wera • 7441 Adjustable Torque Screwdriver 7441 (1.2 → 3Nm)€60.0

Adjustable Kraftform torque screwdriver with Rapidaptor quick-release chuck

Suitable for bits with 1/4" hex head drive

Distinct signal when pre-set value is reached

Numerical torque value indicator

Torque Range: 1.2 → 3Nm

Accuracy: ±6 %

Drive Shape: Hex

Drive Size: 1/4 in

|

Drill & Driver

|

2021-01Bosch • GSR 12V-35 FC Professional (06019H3000)€300

L-BOXX 102 1 600 A01 2FZ

Drill chuck adapter GFA 12-B 1 600 A00 F5H

Bit holder adapter GFA 12-X 1 600 A00 F5J

Angle adapter GFA 12-W Professional 1 600 A00 F5K

Offset angle adapter GFA 12-E 1 600 A00 F5L

Quick charger GAL 12V-40 Professional 1 600 A01 9R3

2 x battery GBA 12V 3.0Ah 1 600 A00 X79

Torque (soft/hard/max.): 20/35/- Nm

Idle speed (1st gear / 2nd gear): 0 – 460 / 0 – 1.750 min-1

Battery type: Lithium-ion

Drill chuck clamping range, min./max.: 0.8 / 10 mm

Battery voltage: 12 V

Torque levels: 20+1

|

|

2018-12Carl Kammerling (C.K) (Germany) • T3010 1 Multi Step 4-20mm Drill€25

2018-12TackLife (China) • PDH06A Step Drill Kit€20

For drilling 8mm holder holes in windows and door. Smallest drill bit has higher steps.

To drill holes in perspex, you can buy specialised drill bits for plastic.

TackLife drill bits are not very precise. For example 10mm part diameters: 9.84mm, 9.50mm, 9.94mm

#1: 4 6 8 10 12mm

#2: 3 5 7 9 11 13 15 17 19mm

#3: 5 7 10 12 14 16 18 20 22mm

#4: 3 4 5 5.5 6 7 8 9 10 11 12 13mm

#5: 8 11 14 17 20 22 25 27 30 32 35mm

Automatic center punch

|

Wire Stripping and Cutting Tools

|

2016-05C.K Tools • 495001 Wire Stripper€19

Stripping: 0.2 - 6.0mm²;

Cutting: HRC 40 - 50;

Crimping: 0.5 - 6.0mm² insulated and non-insulated terminals

|

|

2016-05C.K Tools • Wire Stripping Pliers T3894€18

For safe and damage-free stripping of fine, insulated solid wires in applications where it is critical to prevent damage from electro-static charge. Suitable for cutting soft copper wires.

Stripping capacities mm: 0.4, 0.5, 0.6, 0.8, 1.0, 1.3

Stripping capacities AWG: 26, 24, 22, 20, 18, 16

|

|

2016-05C.K Tools • Side Cutters T3887€14

Precision side cutters for fine cutting applications Sharp, precision ground cutting edges with an extra full flush cut Suitable for cutting soft copper wires of up to 1.6mmØ / 14AWG Tapered and relieved head for access in narrow and confined spaces.

|

Mechanical Pencil

|

2016-01Rotring • 600 Mechanical Pencil 0.5mm€25

• Full metal body providing ideal balance of weight and feeling

• Lead hardness grade indicator for rapid identification

• Hexagonal shape keeps pencil where you want it

• For precise ruler-based drawing, the sliding sleeve provides a high level of break resistance and an unimpeded view of the page

|

Jocys.com

Comments • 0

|

|

|

PETG Filament

PETG Filament

|

I would not recommend to print parts from ABS (shrinkage is too big) or PLA (low heat resistance).

2018-05Prusa3D • Jet Black Prusament PETG 1.75€32

2020-08MCPP • BasicFil PETG 1.75€21

2020-08Amazon • AmazonBasics PETG 1.75€21

From identical design of spools, silica-gel sachets, temperature recommendations, printing results, similar prices on Amazon and that both are manufactured in Netherlands... AmazonBasics PETG filament can be rebranded BasicFil PETG by Mitsubishi Chemical Performance Polymers (MCPP) Netherlands B.V., one of the world's largest polymer based 3d filament manufacturers.

From design of the spools, 3DPrintz PETG filament can be rebranded PETG K5 by NorthBridge3D (China) sub-brand Kexcelled (China). They claim, that they are "The largest 3D filament manufacturer in East China".

|

|

3DPrintz

Prusa3D / Filament-PM

Real-Filament

3DPrintz |

|

|

2018-05SHL • Isopropanol / Isopropyl Alcohol / IPA€15

For preparing-cleaning heated printer bed... Double-sided Textured PEI Powder-coated Spring Steel Sheet before printing with PETG filament.

For thin parts to stick correctly, you may need to adjust height of first layer perfectly and to reduce "Elephant foot compensation" from default value 0.2mm... to 0.1mm.

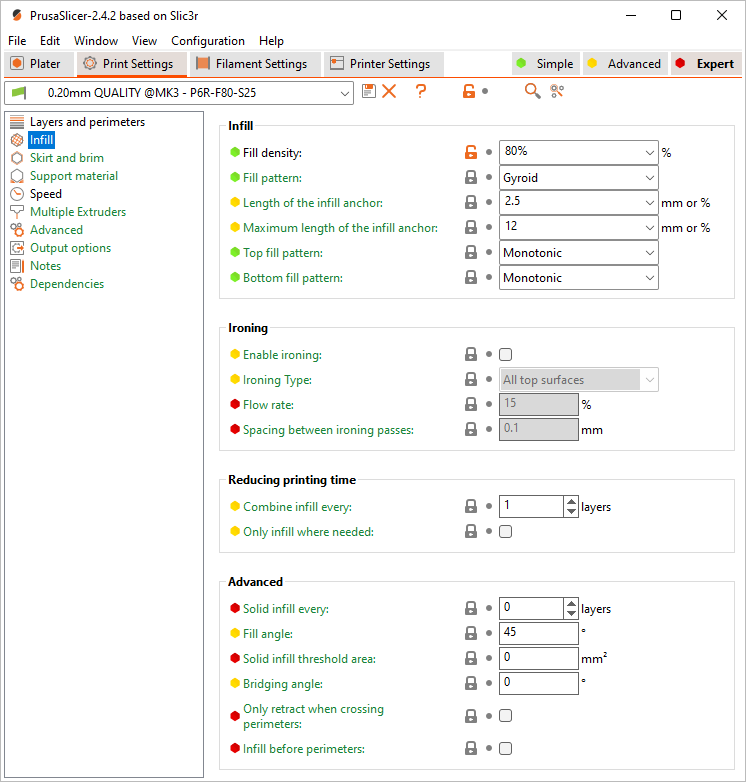

Modified settings: PrusaSlicer > Print Settings > 0.20 QUALITY MK3 > Advanced > Slicing... Modified settings: PrusaSlicer > Print Settings > 0.20 QUALITY MK3 > Advanced > Slicing...

Isopropanol 99.9% / Isopropyl Alcohol / IPA

Manufacturer Part Number: 1000-ISO-TRIGGER

Child Proof Cap

Natural Trigger spray cap for bottles with a 28mm neck (OFF, Spray, Stream)

1 Litre

|

|

2018-05PC Johnson • Windex Original Glass Cleaner€8

For preparing-cleaning heated printer bed... Spring Steel Sheet with Smooth Double-sided PEI before printing with PETG filament.

Water: Water

2-Hexoxyethanol:Cleaning Agent

Isopropanolamine: Cleaning Agent

Ammonium Hydroxide: Cleaning Agent

Lauryl Dimethyl Amine Oxide: Wetting Agent

Sodium Dodecylbenzene Sulfonate: Wetting Agent

Fragrance: Fragrance

Liquitint® Sky Blue Dye: Dye

|

Jocys.com

Comments • 0

|

|

|

Printing Settings

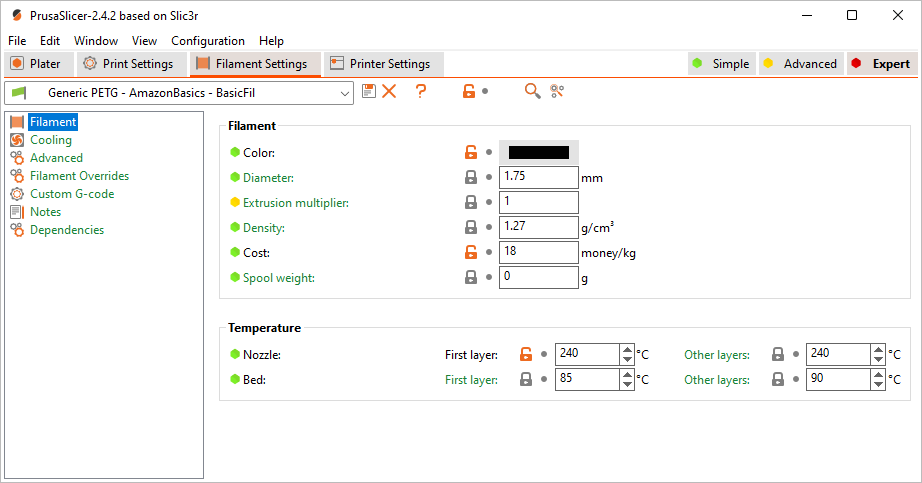

Printing Settings for PETG Filament on TEXTURED PEI Powder-coated Spring Steel Sheet

For BIG parts to stick on TEXTURED PEI Powder-coated Spring Steel Sheet, I increased bed temperature for AmazonBasic • BasicFil PETG filaments from recommended 60-80°C to 85°C (First layer) and 90°C (Other layers). I printed BIG parts in my own Temperature Controlled Enclosure. Temperature inside enclosure was 35°C. E3D V6 HotEnd is rated to 40°C ambient operating temperature. As you approach that temperature, cooling efficiency is reduced, allowing more heat up past the heatbreak. This can cause low temperature filament to soften in the mechanism to cause feed problems.

Temperature

|

PrusaSlicer ► PrusaSlicer ►  Filament Settings ► Filament Settings ►  Generic PETG (modified) ► Generic PETG (modified) ►  Filament ► Filament ►

Temperature ►

Nozzle:

First layer: 240 °C First layer: 240 °C

Other layers: 240 °C Other layers: 240 °C

Bed:

First layer: 85 °C First layer: 85 °C

Other layers: 90 °C Other layers: 90 °C

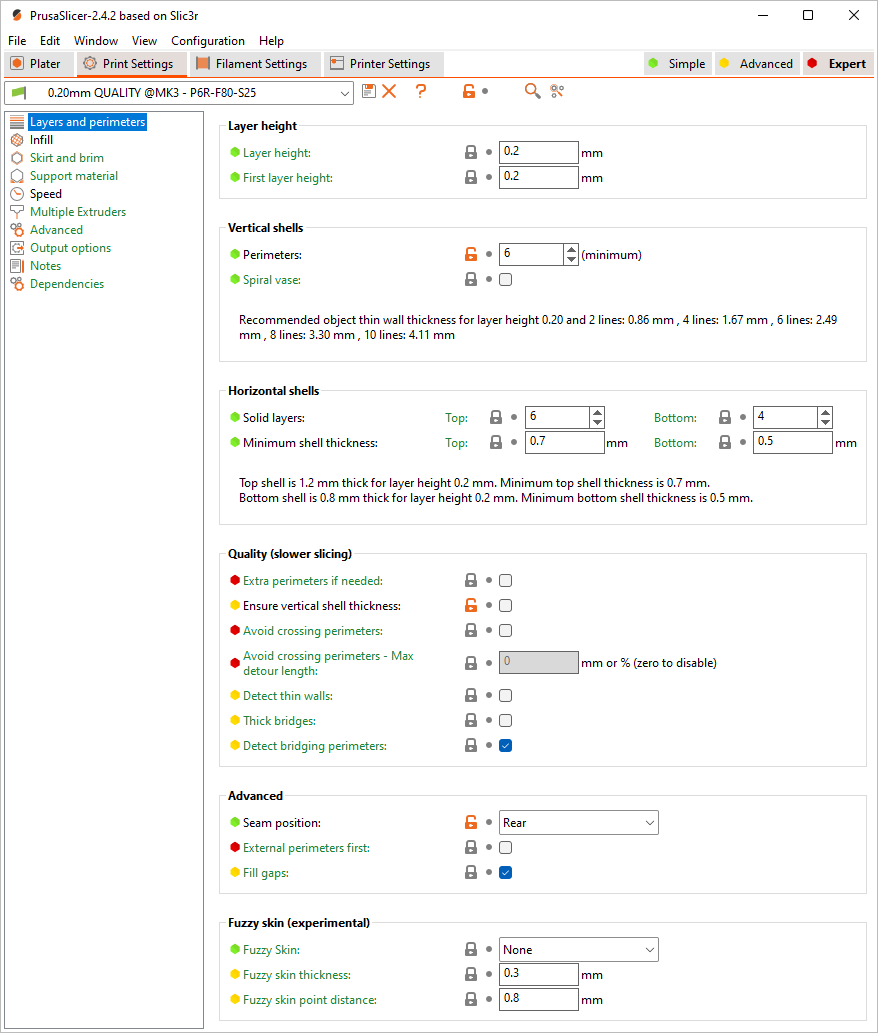

Layers and Perimeters

PrusaSlicer ► PrusaSlicer ►  Print Settings ► Print Settings ►  0.20 QUALITY MK3 (modified) ► 0.20 QUALITY MK3 (modified) ►  Layers and perimeters ► Layers and perimeters ►

Vertical shells ►

Perimeters: 6 (minimum) Perimeters: 6 (minimum)

Quality (slower slicing) ►

Ensure vertical shell thickness: disabled - I had problems with thin 45° hanging angles when it was enabled. Ensure vertical shell thickness: disabled - I had problems with thin 45° hanging angles when it was enabled.

Advanced ►

Seam position: Rear - created line at the back of the parts, but front and side surfaces were perfectly smooth. Seam position: Rear - created line at the back of the parts, but front and side surfaces were perfectly smooth.

Infill

PrusaSlicer ► PrusaSlicer ►  Print Settings ► Print Settings ►  0.20 QUALITY MK3 (modified) ► 0.20 QUALITY MK3 (modified) ►  Inflill ► Inflill ►

Infill ►

Fill density: 80% Fill density: 80%

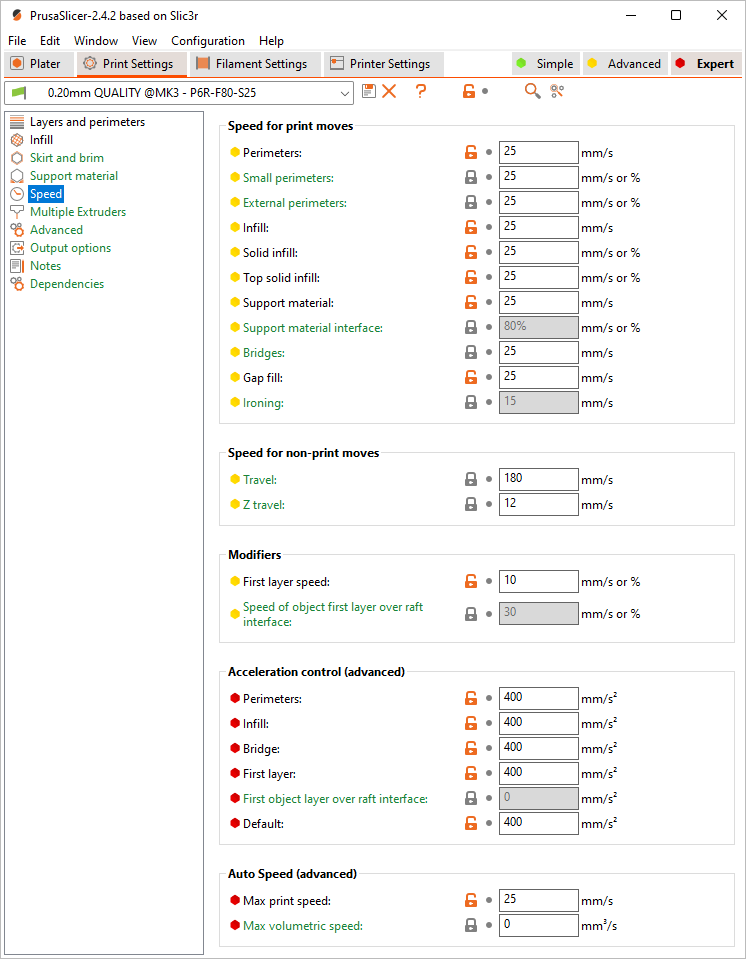

Speed

PrusaSlicer ► PrusaSlicer ►  Print Settings ► Print Settings ►  0.20 QUALITY MK3 (modified) ► 0.20 QUALITY MK3 (modified) ►  Speed ► Speed ►

Speed for print moves ►

All speeds (except greyed out - locked fields): 25 mm/s or % - slower printing speeds (10-25-180-400), results in smoother and glossier surfaces without matte areas, reduces printing noise and vibrations - lesser probability for corners of big parts to unstick from heated bed, because of shrinking. All speeds (except greyed out - locked fields): 25 mm/s or % - slower printing speeds (10-25-180-400), results in smoother and glossier surfaces without matte areas, reduces printing noise and vibrations - lesser probability for corners of big parts to unstick from heated bed, because of shrinking.

Modifiers ►

First layer speed: 10 mm/s or % - for better adhesion. First layer speed: 10 mm/s or % - for better adhesion.

Acceleration control ►

All speeds (except greyed out - locked fields): 400 mm/s² All speeds (except greyed out - locked fields): 400 mm/s²

Auto speed (advanced) ►

Max print speed: 25 mm/s Max print speed: 25 mm/s

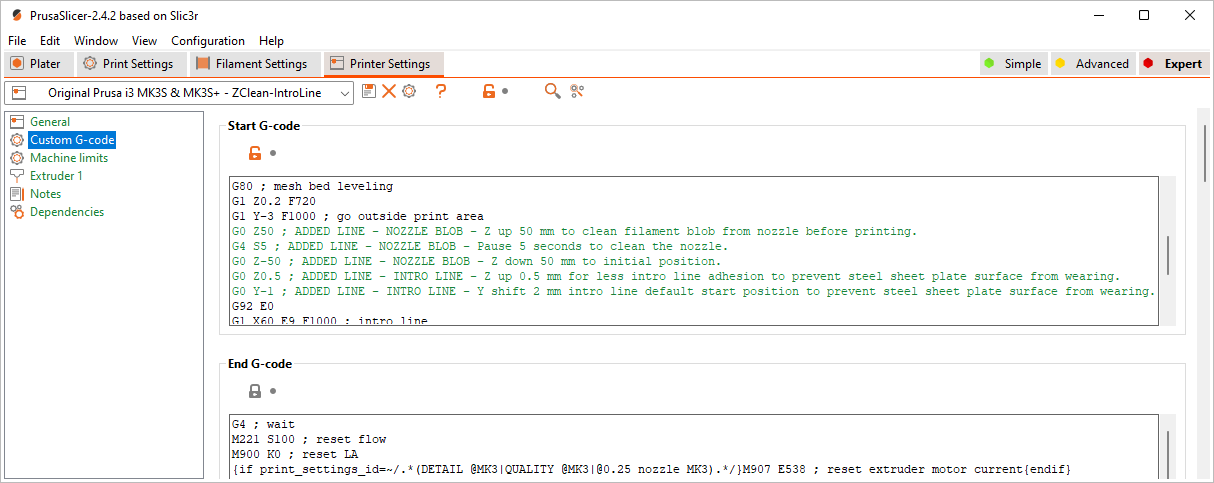

Custom G-Code

PrusaSlicer ► PrusaSlicer ►  Printer Settings ► Printer Settings ►  Original Prusa i3 MK3S (modified) ► Original Prusa i3 MK3S (modified) ►  Custom G-code ► Custom G-code ►

Start G-code ►

G0 Z50 ; ADDED LINE - NOZZLE BLOB - Z up 50 mm to clean filament blob from nozzle before printing.

G4 S5 ; ADDED LINE - NOZZLE BLOB - Pause 5 seconds to clean the nozzle.

G0 Z-50 ; ADDED LINE - NOZZLE BLOB - Z down 50 mm to initial position.

G0 Z0.5 ; ADDED LINE - INTRO LINE - Z up 0.5 mm for less intro line adhesion to prevent steel sheet plate surface from wearing.

G0 Y-1 ; ADDED LINE - INTRO LINE - Y shift 2 mm intro line default start position to prevent steel sheet plate surface from wearing.

|

Jocys.com

Comments • 0

|

|

|

STL Files

STL Files

For better quality and safety... I printed majority of parts separately.

|

To split group and to remove some parts:

1. Open “*.STL” file in PrusaSlicer Edition.

2. Click on [ Split to objects ] button.

3. Select parts one by one, which you don't want to print.

4. Press [ Del ] key on keyboard.

|

|

You can edit STL files with free and open source 3D creation suite Blender.

|

|

Import “*.STL” file:

- Blender 2.8 ► File ► Import ► Stl (.stl).

If imported STL object is not visible:

- Select imported object in “Scene Collection” list (top-right panel).

- In “Object Mode“ (top-left drop-down) ► Object ► Set Origin ► Geometry to Origin.

|

|

Helpers_Table_Corner.STL

1 x Corner screw predrill helper (3mm drill)

1 x Corner leg end alignment helper

1 x Corner leg holder alignment helper

|

|

Helpers_Leg_Ends.STL

1 x Leg end predrill helper (3mm drill)

1 x Leg end alignment helper

1 x Leg end alignment helper spacer

|

|

Helper_A_Table_Holes.STL

1 x Helper A

- 22mm filament hole (top, bottom)

- 22mm controller power cable / temperature sensor hole (top, bottom)

- 22mm PSU power cable hole (top, bottom)

- 22mm motion sensor hole (bottom)

- 32mm motion sensor hole (bottom)

- 54mm fan holes (top, bottom)

|

|

Helper_B_Table_Holes_LED.STL

1 x Helper B

- LED holder distance from table edges

- LED holder corner screw positions (bottom)

- 22mm cable hole (bottom)

- 22mm cable hole and cable box screw positions (back)

- 32mm motion sensor hole (front)

|

|

Helpers_Window_Holes.STL

1 x Windows 8mm holes helper

|

|

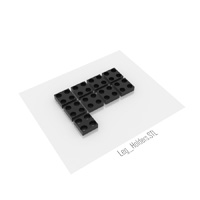

Leg_Holders.STL

4 x Leg holder for bottom table tabletop

4 x Leg holder for middle table tabletop

1 x Leg holder for middle table tabletop ±1mm (door) - if door is not aligned perfectly

|

|

Table_2_Leg_Bottom_Ends.STL

4 x Table 2 (middle) leg bottom end

|

|

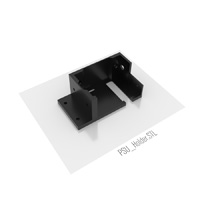

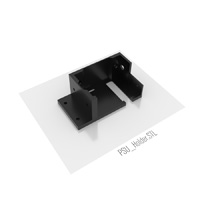

PSU_Holder.STL

1 x Prusa3D i3 MK3 printer PSU holder

|

|

PSU_Bracket.STL

1 x Prusa3D i3 MK3 printer PSU bracket

|

|

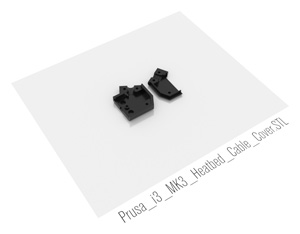

Prusa_i3_MK3_Heatbed_Cable_Cover_Small.STL

Replaces original Prusa i3 MK3 heatbed cable cover and changes orientation of heatbed cable, so it does not crash into back window of Ikea LACK enclosure. This is reinforced version of Prusa i3 MK3 Angled Heatbed Cable Cover STL by FlyingProf.

1 x Prusa i3 MK3 Heatbed Cable Cover Top

1 x Prusa i3 MK3 Heatbed Cable Cover Top

|

|

Tubes.STL

2 x 54mm fan tube

2 x 54mm tube clip

1 x 22mm filament tube

1 x 22mm PSU power cable tube

1 x 22mm controller power cable / temperature sensor tube

3 x 22mm tube clip

|

|

LED_Holders.STL

For 8mm width LED strips, cutted to 40cm length pieces.

!!!DON’T peel off self-adhesive backing’s protective covering from LED strips. LED strips slide into holders, not stick to them. Clips will hold LED strips in place and allow removal.

4 x LED strip (in-in)

4 x LED strip (in-out)

|

|

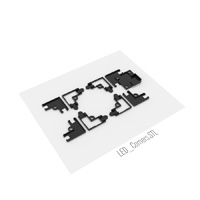

LED_Corners.STL

For 8mm width LED strips.

3 x LED corner

3 x LED corner cover

1 x LED corner (cable)

1 x LED corner cover (cable)

|

|

Cables.STL

1 x Power connection box

1 x Power connection box cover

1 x 22mm motion sensor cable hole cover

1 x 32mm motion sensor cable hole cover

1 x 32mm motion sensor cable hole cover holder

1 x Motion sensor holder

2 x Motion sensor holder clips

8 x Cable holder 3.5x7mm

8 x Cable holder 3.5x7mm (for LED holder holes)

2 x Cable holder 3.5x7mm (for LED holder holes) (center)

1 x Cable holder 3.5x7mm (center)

1 x Cable holder 3.5x7mm / temperature sensor holder 2 x 3.5x3.5mm

|

|

Table_3_Leg_Top_Ends.STL

1 x Leg end (door)

1 x Leg end (magnet)

1 x Leg end (back-left)

1 x Leg end (back-right)

1 x Table corner leg holder (door)

1 x Table corner leg holder (magnet)

1 x Table corner leg holder (back-left)

1 x Table corner leg holder (back-right)

|

|

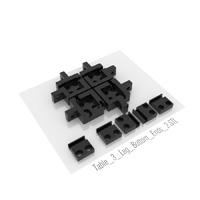

Table_3_Leg_Bottom_Ends.STL

1 x Leg end (door)

3 x Leg end

|

|

Door.STL

Fill density exception for windows and door holding parts:

PrusaSlicer ► Print Settings ► Infill ► Fill density: [ 60% ]

2 x Door handle

1 x Door handle spacer - door handle in file is 216mm, but printed (shrunk) 215mm. Added spacer.

1 x Door handle connector

2 x Door hinge

4 x Door hinge holder

2 x Door holder

2 x Door holder clip

2 x Magnet insert holder

4 x Magnet insert

4 x Magnet insert cover

|

|

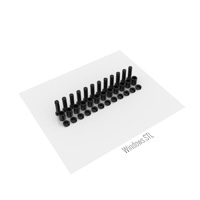

Windows.STL

Fill density exception for windows and door holding parts:

PrusaSlicer ► Print Settings ► Infill ► Fill density: [ 60% ]

12 x Window holder

12 x Window holder spacer

12 x Window holder clip

|

|

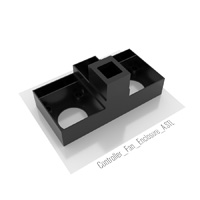

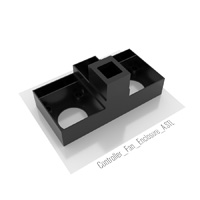

Controller_Fan_Enclosure_A.STL

1 x Controller and fan enclosure part A

|

|

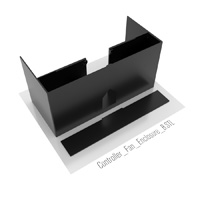

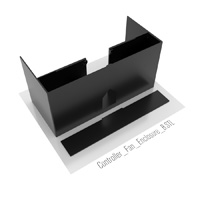

Controller_Fan_Enclosure_B.STL

1 x Controller and fan enclosure part B

1 x Controller and fan enclosure part B cable cover - Bridging angle exception:

PrusaSlicer ► Print Settings ► Infill ► Bridging angle: [ 45 ] °

|

|

Controller.STL

2 x Controller front panel

2 x Controller stopper

|

|

Filament_Holder.STL

1 x Filament Holder Connector

1 x Filament Holder Left

1 x Filament Holder Right

|

|

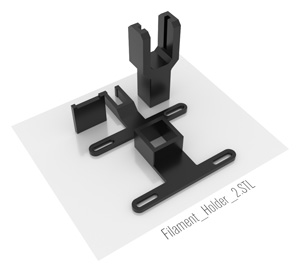

Filament_Holder_2.STL

1 x Filament Guide for Filament Holder Connector

1 x Filament Holder for Prusa3D Filament Holder (Optional)

1 x Filament Holder Plate for Prusa3D Filament Holder (Optional)

1 x Filament Guide for Prusa3D Filament Holder (Optional)

|

STL Files (Optional)

|

Table_3_Leg_Bottom_Ends_Cables.STL

Parts if you need additional holes for cables.

1 x Leg end (door)

3 x Leg end

1 x Leg holder ±1mm (door) - if door is not aligned perfectly

4 x Leg holder

|

File for Editing (Optional)

Jocys.com

Comments • 0

|

|

|

Assembly

Assembly

Table 1 (Bottom)

PREDRILL

|

1. Pre-drill tabletop top corners. 4 srew holes for each corner.

- Use helper from “Helpers_Table_Corners.STL” file.

- Use 3mm wood drill bit.

|

|

LEGS

|

2. Screw-on table legs with Ikea screws.

|

Table 2 (Middle)

HOLES

|

1. Mark PSU cable hole position on tabletop top and bottom.

- Use “Helper A” from “Helper_A_Table_Holes.STL” file.

- Use mechanical pencil.

2. Drill 22mm diameter PSU cable hole in tabletop top and bottom.

- Use 22mm wood spade drill bit.

|

|

PREDRILL

|

1. Pre-drill tabletop top corners. 4 srew holes for each corner.

- Use helper from “Helpers_Table_Corners.STL” file.

- Use 3mm wood drill bit.

|

|

LEGS

|

2. Screw-on table legs with Ikea screws.

|

|

3. Pre-drill table leg ends. 4 screw holes for each leg.

- Use helper from “Helpers_Leg_Ends.STL” file.

- Use 3mm wood drill bit.

|

|

PSU

|

1. Replace Prusa3D i3 MK3 printer's PSU with printed PSU bracket.

- Use parts from “PSU_Bracket.STL” file.

|

|

|

2. Screw-on PSU holder to right-back leg if table is upside-down (near PSU cable hole).

- Use part from “PSU_Holder.STL” file.

- Use 4 SPaX screws.

- Use Torx T20 bit.

- Use 15cm bit extension or angle ratchet tool to reach and screw 1 of 4 screw.

3. Align PSU holder to tabletop and screw it to tabletop.

- Use 2 SPaX screws.

- Use Torx T20 bit.

|

|

|

4. Insert 22mm tube into PSU cable hole from the top and clip it with 22mm clip-ring from the bottom.

- Use parts from “Tubes.STL” file.

|

|

Table 3 (Top)

HOLES

|

1. Mark and drill 22mm diameter cable hole in tabletop back (12V connection box ).

- Use “Helper B” from “Helper_B_Table_Holes_LED.STL” file

- Use mechanical pencil.

- Use 22mm wood spade drill bit.

2. Mark 12V connection box 5 screw positions.

- Use mechanical pencil.

- Use awl, YackLife automatic center punch or similar tool.

|

|

|

3. Mark and drill 22mm diameter cable hole in tabletop bottom-back (inner LED corner).

- Use “Helper B” from “Helper_B_Table_Holes_LED.STL” file.

- Use mechanical pencil.

- Use 22mm wood spade drill bit.

|

|

|

4. Mark and drill 32mm diameter “motion sensor” hole in tabletop front-center (motion sensor).

- Use “Helper B” from “Helper_B_Table_Holes_LED.STL” file.

- Use mechanical pencil.

- Use 32mm wood spade drill bit.

|

|

|

5. Mark 22mm “sensor cable” and 32mm “sensor insert” hole positions on tabletop bottom.

- Use “Helper A” from “Helper_A_Table_Holes.STL” file.

- Use mechanical pencil.

6. Drill 22mm diameter “sensor cable” hole in tabletop bottom.

- Use 22mm wood spade drill bit.

7. Drill 32mm diameter “sensor insert” hole in tabletop bottom.

- Use 32mm wood spade drill bit.

|

|

|

8. Connect main “Helper A” part with “filament hole” extension part.

- Use parts from “Helper_A_Table_Holes.STL” file.

9. Mark 4 hole positions on tabletop top and bottom.

- 22mm filament hole

- 22mm controller power cable / temperature sensor hole.

- 54mm fan hole.

- 54mm fan hole.

- Use “Helper A” from “Helper_A_Table_Holes.STL” file.

- Use mechanical pencil.

10. Drill holes in tabletop bottom and top.

- Use 22mm wood spade drill bit.

- Use 54mm holesaw drill bit (kit) for 54mm holes.

Other drilling tools may not be precise enough.

|

|

|

PREDRILL

|

1. Pre-drill tabletop corners from top and bottom. 4 screw holes for each corner.

- Use helper from “Helpers_Table_Corners.STL” file.

- Use 3mm wood drill bit.

|

|

LED and CABLES

|

1. Mark 4 corner positions of LED screws on tabletop bottom corners.

- Use helper from “Helper_B_Table_Holes_LED.STL” file.

- Use Mechanical pencil.

|

|

|

2. Cut LED strips into four 40cm pieces.

- !!!DON’T peel off self-adhesive backing’s protective covering from LED strips. LED strips slide into holders, not stick to them. Clips will hold LED strips in place and allow removal.

- One of the pieces must end with 12V female connector.

|

|

3. Slide LED strip 40cm pieces into led holders and corners (“+” must be connected to “+”).

- Use parts from “LED_Holders.STL” file.

- Use parts from “LED_Corners.STL” file. Hole-connection corner parts are different.

4 Connect 3 LED strip 40cm pieces with 3 LED corner connectors.

- LED strip corner connectors are in “Ustellar” LED light set.

5. Prepare 12V cables and connectors.

- Use C.K Tools 495001 Wire Stripper.

- Use HitCar 7M 5.5mm x 2.1mm 12V DC power cable.

- Use 3 female 5.5mm x 2.1mm 12V DC power connectors.

- Use 2 male 5.5mm x 2.1mm 12V DC power connectors.

|

|

SENSOR

|

1. Insert motion sensor holder through 32mm tabletop front hole.

- Use part from “Motion_Sensor.STL” file.

2. Insert motion sensor through 32mm tabletop bottom hole

- Use Tuodi TDL-2024 5V-24V motion sensor switch.

3. Push motion sensor into motion sensor holder.

4. Use pliers to insert motion sensor clip through 32mm tabletop bottom hole and slide it into holder’s bottom track. Then use fingers to push clip forward, until clip is locked.

5. Slide second motion sensor clip into holder's top track the same way.

- Use parts from “Motion_Sensor.STL” file.

|

|

|

6. Hide motion sensor cable connections inside the table and cover them with cover.

- Use parts from “Cables.STL” file.

|

|

LEG HOLDERS

|

2. Insert door hinge holders with door hinge into one of the leg holders.

- Use parts from “Door.STL” file.

|

|

POWER CONNECTION BOX

|

1. Screw onto table 12V power connection box.

- Use parts from “Cables.STL” file.

- Use 16 SPaX screws.

- Use Torx T20 bit.

|

|

LEGS

|

1. Pre-drill TOP (hole in the center) leg ends. 4 screw holes for each leg.

- Use helper from “Helpers_Table_Legs.STL” file.

- Use 3mm wood drill bit.

|

|

|

3. Pre-drill BOTTOM leg ends. 4 screw holes for each leg.

- Use helper from “Helpers_Table_Legs.STL” file.

- Use 3mm wood drill bit.

|

|

WINDOWS

FILAMENT

|

1. Insert 22mm tube into “filament” hole from the top and clip it with 22mm clip-ring from the bottom.

• Use part from “Tubes.STL” file.

|

|

CONTROLLER ENCLOSURE

|

2. Screw “Controller Fan Enclosure A” part to the table.

- Use part from “Controller_Fan_Enclosure_A.STL” file.

- Use 16 SPaX screws.

- Use Torx T20 bit.

|

|

FANS

|

1. Insert fan cables into controller enclosure holes and then insert fan. Back side first, then front side.

- Use 2 Noctua NF R8 redux 1800 80mm fans.

|

CONTROLLERS

|

1. Remove orange plastic. Push “half-circle” part (this will rise pin from toothed groove) and you will be able to remove orange plastic by sliding it to the back.

|

|

2. Wire controller cables and connections to controller.

|

|

3. (Optional) Remove original controller front plate and attach printed one. Original front plate is not glued, but holds on 6 pins, like printed front plate part. In my case, one pin from original plate stuck and broke, when I tried to remove original front plate from controller. I used small drill to clean pin from the hole.

- Use part from “Controller.STL” file.

4. Slide controller stopper onto controller from the back.

- Use part from “Controller.STL” file.

|

|

|

5. Slide controllers into “Controller Enclosure Part B” controller mounting slots from the front.

- Use part from “Controller_Fan_Enclosure_B.STL” file.

6. Put “Controller Fan Enclosure B” on “Controller Fan Enclosure A”.

|

|

CONTROLLER CONNECTIONS

|

1. Connect fans and power cables to controller.

|

TEMPERATURE SENSOR

|

1. Push controller temperature sensors through 22mm cable hole and screw them to the tabletop with temperature sensor clip.

|

DOOR

|

1. Attach magnets to the table.

- Use parts from “Door.STL” file.

- Use 4 2x6mm magnets.

|

|

|

2. Attach Door to the table with door hinges, door holders and clips.

- Use parts from “Door.STL” file.

3. Attach door handle and magnets to the door.

|

|

FILAMENT HOLDER

|

1. Assemble and attach filament holder.

- Use parts from “Filament_Holder.STL” file.

|

|

PUT ALL 3 TABLES ON TO EACH OTHER

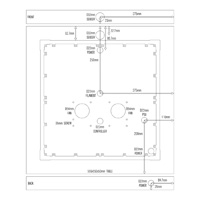

Dimensions

|

Dimensions (Table)

Table Holes and Helpers

|

|

Dimensions (Windows and Door)

Window and Door Holes and Helpers

|

Jocys.com

Comments • 1

|

|

|